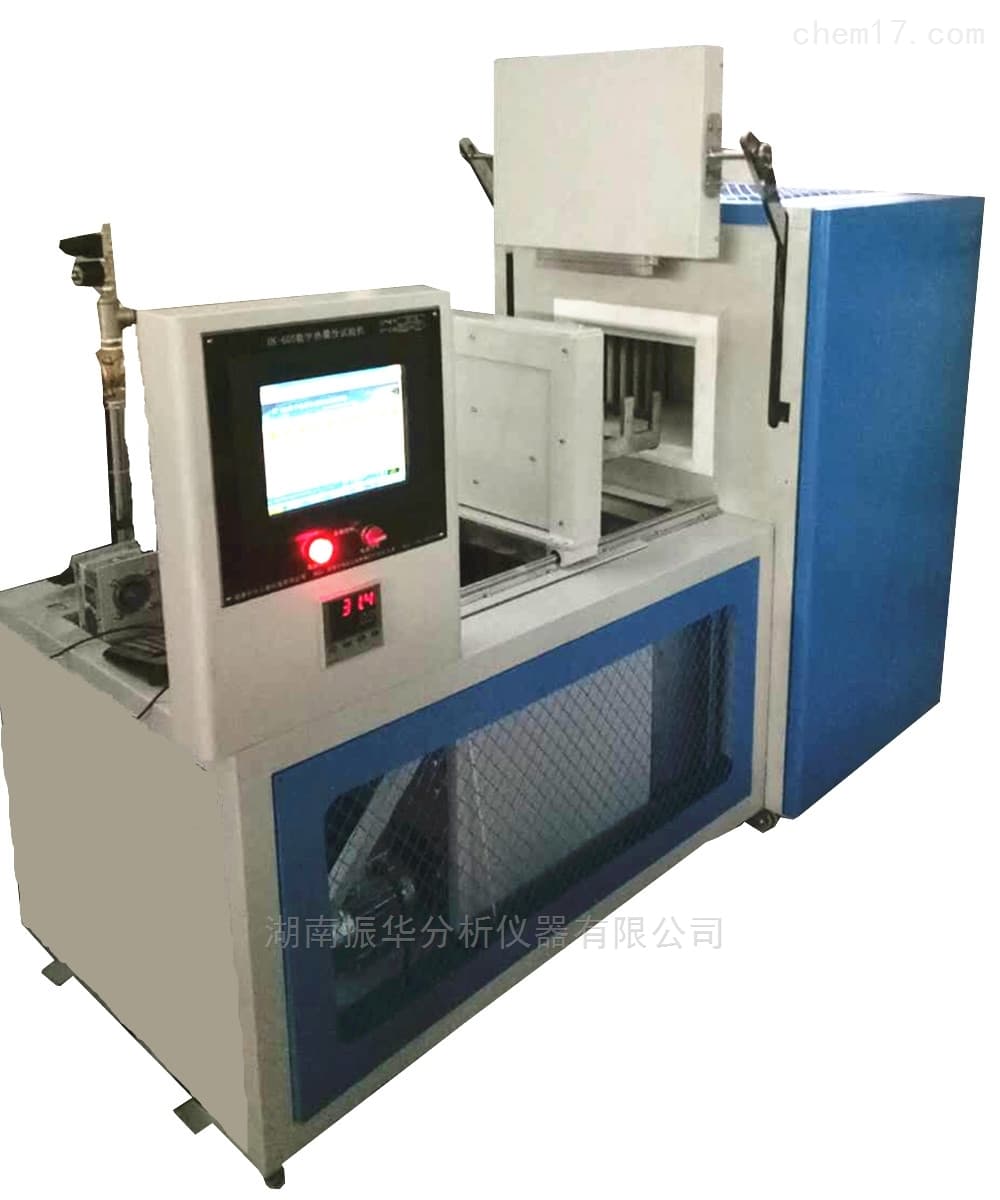

Automatic Refractory Thermal Shock Resistance Tester

Published: 5/22/2019

The instrument evaluates the thermal shock resistance of refractory materials according to YB/T 376.1 testing standards. It is used primarily in testing refractory products, ceramics, glass, and other non-metallic materials.

Product Description

The RZL-II-14 Automatic Refractory Thermal Shock Resistance Tester is designed to measure the thermal shock resistance of materials. It is manufactured in compliance with YB/T 376.1 and YB/T2206.1-1998 standards. The device features horizontally rotating sample holders for easy sample loading and end surface fracture observation.

This equipment is suitable for testing refractories, ceramics, glass, and various non-metallic and graphite materials. It offers the option of testing using either compressed air or water quenching methods. The machine incorporates Siemens PLC for fully automatic control, allowing for manual operation if required.

The device is equipped with a 12-inch touch screen industrial control computer, providing a graphical user interface for data display and process parameter settings. Features include comprehensive safety alarms such as overtemperature and emergency stop functions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum Furnace Temperature | 1400°C |

| Temperature Uniformity Range | ±2°C |

| Sample Size | Based on customer samples |

| Heating Chamber Dimensions | 300×200×220 mm |

| Sample Capacity | 3 standard bricks |

| Compressed Air Pressure | 0.1 MPa |

| Compressed Air Nozzle Size | 8×5 mm |

| Water Bath Temperature Control Range | 10-50°C |

| Water Bath Temperature Uniformity | ±2°C |

| Temperature Resolution | 0.1°C |

| Water Bath Heating Power | ≤6 kW |

| Cooling System Power | 3 kW |

| Water Pump Power | 120 W |

| Power Supply | 380V/50Hz, 3-phase |

| Total Power | 15 kW |

| Control System | Siemens PLC |

| Alarm And Protection | Overtemperature, thermocouple fail, emergency stop |

Contact Us for Pricing

Interested in this product? Reach out for a personalized quote or more information. Our team will respond within 24 hours.

Send us a Message

Contact Information

Phone

Office

Address

B6-101, Zhongnan High-Tech Intelligent Manufacturing Industrial Park, No. 10 Shuangma Street, Yuetang District, Xiangtan City, Hunan Province, China

Scan to connect on WeChat